The foundation of numerous sectors, industrial equipment drives activities in manufacturing, transportation, agriculture, and more. Regular maintenance and refilling are really vital to guarantee this equipment run effectively and consistently. These upkeep techniques not only increase equipment lifetime but also help to avoid expensive breakdowns. Technologies like fluid transfer pumps have simplified these procedures even further, increasing their efficiency and reducing their time required.

Improving Tools Longevity with Lubrication

Reducing friction and wear between moving components of industrial equipment depends critically on lubrication. Components under more stress without appropriate lubrication risk overheating, distortion, and finally failure. Frequent lubrication guarantees a continuous protective layer is kept, therefore reducing direct metal part contact. Advanced technology include automated dispensers and sensors that provide accurate lubricant quantities exactly where they are needed abound in modern lubrication systems. This removes the equally harmful effects of under-lubrication or over-lubrication on machinery. Moreover, these solutions guarantee best operation of their devices and assist businesses save labor and time expenses.

Stopping Downtime with Good Refueling Techniques

In sectors of heavy machinery-dependent businesses, unplanned downtime could cause major financial losses. Inappropriate fuel management is one of the main reasons of downtime. Effective and frequent refueling guarantees that machinery stays running without breaks. Modern refueling systems let IoT technology and automation merge to provide real-time fuel level and consumption rate monitoring. This guarantees precise and quick refills of equipment, therefore avoiding delays brought on by fuel shortages. Automated refueling systems also help to lower the possibility of contamination and spills, therefore protecting the machinery and the surroundings.

Cost-effectiveness of Regular Maintenance

Although frequent lubrication and refueling look like extra maintenance, they are vital investments in the long run efficiency of industrial equipment. Good maintenance lowers the possibility of unexpected malfunctions, which usually call for costly repairs and cause manufacturing losses. Predictive maintenance-capable advanced systems examine machine status and spot any problems before they become more serious. For example, sensors can quickly intervene when they find abnormalities in fuel flow or lubricant viscosity. Early problem solving helps companies to greatly lower repair costs and keeps regular manufacturing schedules.

Advanced Technologies’ Part in Maintenance

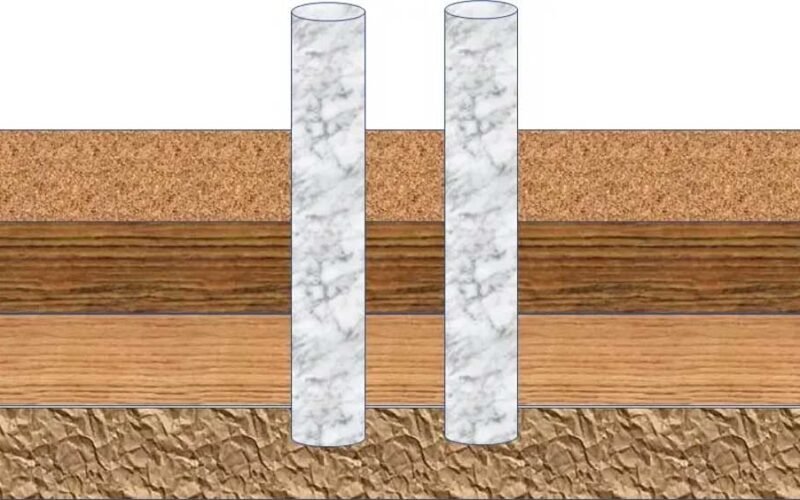

Technological developments have transformed the approach businesses take to lubrication and refueling. By gathering and evaluating data from equipment, IoT-enabled devices reveal operational effectiveness and maintenance requirements. By forecasting, depending on past data and usage trends, when equipment needs maintenance or refilling, artificial intelligence (AI) improves these systems even more. The creation of smart fluid transfer pumps, which guarantee exact fuel and lubricant delivery, is one very innovative invention. These easily handling pumps for a range of fluids help to lower the waste and contamination risk. Combining these technologies will help businesses to reach better degrees of dependability and efficiency in their maintenance procedures.

Environmental Benefits from Frequent Maintenance

A increasing issue in many sectors is sustainability, hence frequent lubrication and refueling help to lower the environmental effect of industrial activities. Furthermore, developments in environmentally friendly fuels and lubricants help businesses to embrace greener methods more easily. Another key component of ecologically conscious maintenance is leak prevention. Modern systems are made to reduce the possibility of leaks and spills, which may seriously damage the surroundings. Investing in sophisticated maintenance technology helps businesses match their operations with environmental laws and lower their carbon impact.

Providing Compliance and Safety

Additionally very important for maintaining job safety are regular lubrication and refilling. In severe circumstances, improperly maintained machinery presents major hazards to operators including overheating, mechanical breakdowns, and even explosions. Regular maintenance makes a safer workplace by helping to find and fix possible dangers. Many sectors also follow rigorous compliance rules requiring consistent equipment maintenance. By means of comprehensive records of maintenance operations, advanced lubrication and refueling technologies streamline compliance and guarantee responsibility and transparency.

To run industrial equipment effectively and dependably, frequent maintenance and refueling are therefore very essential. Industries may simplify these procedures, save expenses, and improve sustainability by using contemporary technology such fluid transfer pumps. The maintenance techniques keeping machines functioning at optimum performance will change as they develop.